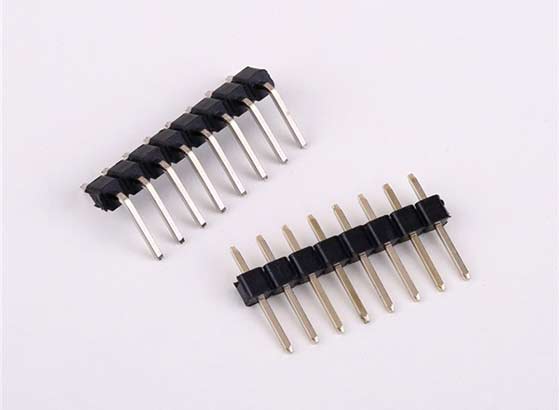

Injection molding

Plastic with Metal inserts,Terminals over mold with plastic,precision over mold terminals

Parts description:

Part Name:Plastic with Metal inserts,Terminals over mold with plastic,precision over mold terminals

Processing Method: Over Molding, insert molding

Surface Treament: EDM texture

Application: insert Molding parts overmolded parts for connector

Mold Information

Mold Material: H13

Mold Cavity: 1X2

Runner: Hot runner insert molding

Design Standard:LKM

Tooling Life: 500-1000K shots

BASIC INFORMATION

Types of Plastic Mold Built

①Prototype Mold

②Single and 2 Shots Injection plastic mold

③Insert Overmold

④MUD Quick Change plastic mold

⑤Silicone Compression molds

Drawing Format

①stp is prefer

②step format

③X_T/Igs

④ PDF / DWG

Plastic Mold Material: Aluminum, Pre-Hardened Steel, Fully Hardened Tool Steel, Copper,Alloys

Plastic Injection Molding Material

①PC, PC/ABS, ABS, PP, PE,PMMA,POM

② Nylon(PA),Glass Reinforced Nylon(PA)

③PBT, PET, LCP,PPS

④TPE, TPU, TPV

⑤Engineering Plastics Thermoplastic Elastomer

Seconday Operations

①Pad Print, Screen Print

②Painting

③Ultrasonic Welding

④Assembly

Industrial Served

①Automotive Components

②Medical and Electronics Parts

③Communication Technology Parts

④Other precision injection molding plastics

TECH AND BUSINESS SUPPORT

Plastic with Metal inserts,Terminals over mold with plastic,precision over mold terminalsBusiness support

1. Sign NDA with all customers if request

2. Accept Low volume business

3.Could turn back the mold charge for High volume projects; for startup companys or old customers lack of money, part of tooling charge could be spared to the production piece price

4. Competive payment terms for long term copperation customer. net 30 days to net 60 days payment terms could be negotiated

5. Logistic support, Tmetal have very competitive logistic chain system, will optimize customer logistic chanel, and offer the best and cost -effective logistic option to all customers

6. customer china local project management and QC managment assitance

Tech support

1. ODM support, tmetal engineers could provide ODM suggestions from cost and manufacturing tech side

2. 3D scanning and 3D model building

3. 100% CNC custom manufacturing for logo, pattern and other special features

4. one stop solution for all mechanical parts from rapid prototype , mold making, to finish parts assembly