TDGHY Tmetal Limited is a professional OEM, ODM manufacturer of hardware products,metal parts and plastic parts and auto checking fixture. Founded and led by our top engineer Mr. Jeff Zhang who with over 15 years of engineering and technology experience in the industry.

Established in Zhangmutou,Dongguan,Guangdong,China, covering an area of about 9,000 square meters with more than 200 sets high precision equipments. We have Precision Casting machines, CNC machines, Lathes, punches, grinders, Laser cutting machines, CNC bending machines, Welding machines, Polishing machines, Plastic Injection machines, Coordinate Measuring Machine(CMM), Projector,etc.

We have CMM(3D coordinate measuring machine) and 2.5D measuring projector, film thickness gauge and other precision gauges, our engineering and manufacturing team are experienced, efficient and dedicated, Strong R&D capacity and strict quality control system enable us to meet customer's unique and difficult products requirements.

We can manufacture non-standard metal and plastic parts and hardware items with high quality and competitive price. Our company are ISO9001: 2015 cetificated, and was audited by SGS-CSTC. Products exported to Europe and America, Australia, middle east and all over the world. Our good quality and prompt services have earned good reputation for our company.

To focus on long-term cooperation, we are in all respects for the customer, effectively help customers save time, energy and cost.We are full of confidence to provide our clients with custom-made solution, and to increase the competence of market share. To be the reliable partner of clients is our eternal objective.Fast delivery and competitive price are our superiority, welcome to experience our products and services, we will do our best to serve you sincerely! We look forward to working with you. Call us now!

Our sustainable, efficient and fast services, can meet the diverse needs of multiple industries from prototypes, trial run, to high-volume production. including automotive/motorcycle,aerospace,medical,electronics, electrical appliances, telecommunication,construction,machinery, marine, furniture, toys, bathroom and Kitchen hardware, water supplying system, lighting system and so on. Now our exports sales turnover are growing at over 30% per year.

Offering one-stop solution from custom design, prototyping, small lot CNC machining, tooling, to large volume casting and moulding production. Anodizing,powder coating,plating,spraying, painting,laser engraving and silk screen are all available to meet the needs of varying applications.

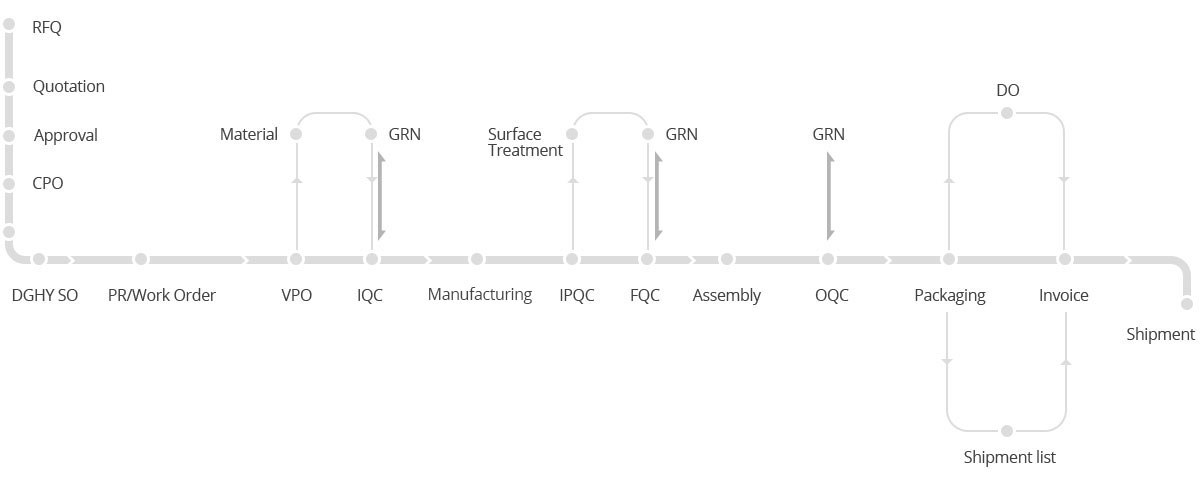

We are a manufacturer that offers design and One-stop Manufacturing Service from concept, initial sketches to final finished products mass production, aim to provide faster, viable engineering technical solutions to our clients to save their time,energy and cost, to make them more cometitive in the market.

Working closely with you to design your concept to final 3D

CMM Machines, Experienced technicians, Closed-loop QC system 3D

800,000pcs monthly of sufficient production capacity

Low MOQ, Fair cost, Engineering and technical solutions

ISO9001: 2015; Certificate Number: 85921 / A / 0001 / UK / En

SGS-CSTC: Audit Report Serial No.: QIP-ASI162393

Learn more about our products